Progressive Die Stamping Process for Geomembrane Fabrication: Overview and Manufacturing Techniques

Progressive die stamping processes are widely used in various industries to shape and fabricate materials into highly durable parts. In this article, we will explore the progressive die stamping process and its application in the manufacturing of geomembranes. Geomembranes are impermeable liners used in environmental and civil engineering projects to contain liquids or prevent the migration of contaminants.

Progressive Die Stamping Process Overview:

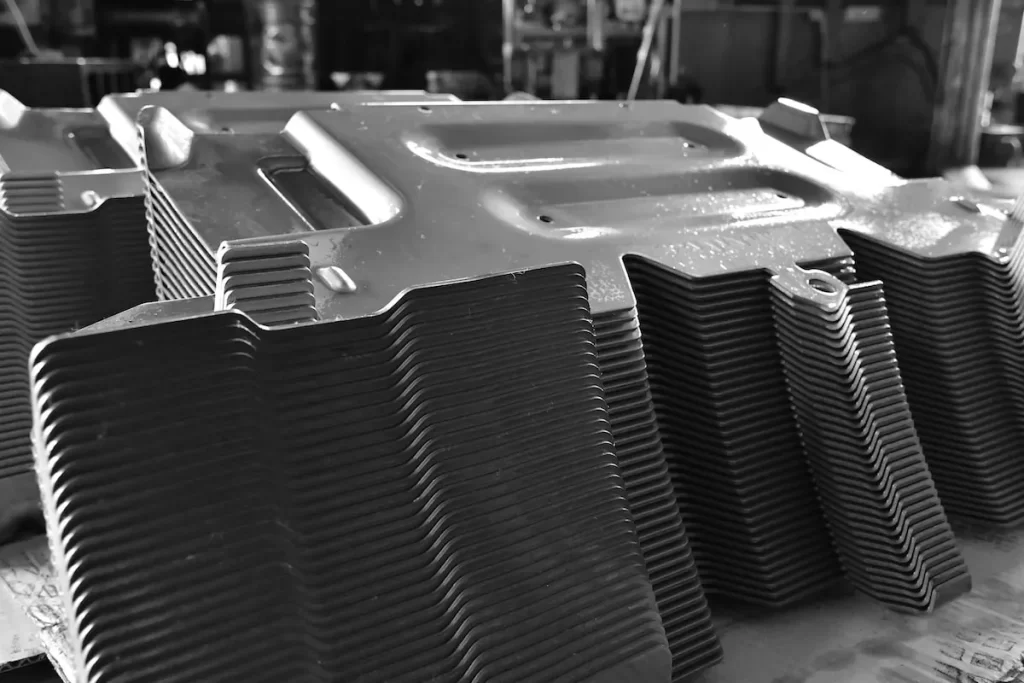

The progressive die stamping process involves a series of workstations where metal strips are fed through to perform shaping and fabrication actions. This process is known for its high-speed operation, enabling large-scale replication of parts. With the integration of geomembrane production, progressive die stamping offers an efficient and precise method for manufacturing these specialized liners.

Four Stages of Progressive Die Stamping Process:

- Proper Positioning: A progressive die is positioned into a stamping press to ensure proper opening and closing functionality during the pressing operation.

- Blanking and Forming: Metal strips are fed through the stamping die, and each press stroke executes precise blanking and forming actions. Some stamping dies also have automatic material removal features, increasing the level of automation.

- Progressive Process: The feed automatically moves the metal strip to the next station, where a different process is performed progressively to achieve the intended design. In the context of geomembrane production, this stage involves specialized actions to create the required shape, thickness, and surface characteristics.

- Final Part Separation: At the final station, the finished geomembrane part is cut free from the feed line. This part can then undergo further processing or assembly, depending on the specific application requirements.

Manufacturing Techniques for Geomembranes:

To achieve ultra-high tolerance standards in geomembrane production, manufacturers employ several key techniques:

- Stock Strip Layout & Design: Advanced computational models are used to design the progressive die, optimizing the positioning of every punch, bend, and hole on the blank strip. This ensures precise and accurate fabrication of geomembrane liners.

- Wire EDM: Electrically charged brass wire is utilized to shape the die blocks through a controlled metal spark. Wire EDM processes enable the creation of intricate shapes, angles, and contours with cutting tolerances as low as ±2 µm. The resulting geomembranes exhibit superior dimensional accuracy and surface quality, with surface finishes as low as Ra 0.1 µm.

- Die Assembly: Skilled engineers assemble the die according to the exact specifications of the original design, using precision instruments. This meticulous assembly process ensures the proper alignment and functioning of the die during the progressive stamping operation.

Progressive die stamping offers a highly efficient and precise method for manufacturing geomembranes. By integrating the progressive die stamping process into geomembrane fabrication, manufacturers can achieve the required shape, thickness, and surface characteristics with exceptional accuracy and repeatability. With its ability to operate at high speeds and replicate parts on a large scale, progressive die stamping is a valuable technique for the production of high-quality geomembranes used in diverse environmental and civil engineering applications.