Custom Stainless Steel Profiles: Sloped Flange Beams

Laser welding is known throughout the architectural, engineering and industrial markets as the only technology that can produce sharp corner steel profiles. While sharp, 90° corners are the standard, one of the major advantages of laser-welded profiles is the ability to customize all aspects of a particular shape including the slope of the flange. These stainless steel, sloped-flange beams are perfect for industrial areas such as food processing where run-off is an issue

Stainless Steel in Food Processing

Food and beverage processing facilities must follow very strict sanitary guidelines from the FDA and other regulators to prevent product contamination. In comparing the different metals, there is no better material to help prevent corrosion and contagion than stainless steel. Aluminum is too soft and is prone to cracks, pitting and white rust. Carbon steel rusts and corrodes very easily. Both of these would bring on very costly repairs, equipment failure and product contamination. All are prevented by using stainless steel.

There are several grades of stainless steel that can be used in food processing but the most common is type 316. This grade provides excellent corrosion and pitting resistance which are critical features of the inherent operation. It has a non-reactive surface, is fire resistant, easy to clean and performs excellent in extreme temperatures. All of these characteristics are what make 316 stainless the perfect choice for food processing and why many call type 316 “food-grade stainless steel”.

The most common applications of stainless steel in food processing include conveyors, tanks, machinery, processing equipment, containers, structural supports, racks and more. As one can imagine, food and beverage production puts these conveyors and equipment through extreme conditions. To meet scrupulous code, food processing equipment has to be cleaned to the same standards as food prep surfaces. This includes a daily cleaning using hot water and disinfectants on all of the equipment and supports.

Sloped Flange Stainless Steel Beams

One issue that has immerged with the cleaning of food processing lines is the contamination of the interior walls of stainless steel tubing used in the structural elements of these production lines. Water and chemicals from the cleanings can leak into the interior walls causing it to corrode from the inside out. To prevent this, many designs are now eliminating the use of hollow tubes altogether and going with structural shapes such as stainless steel beams.

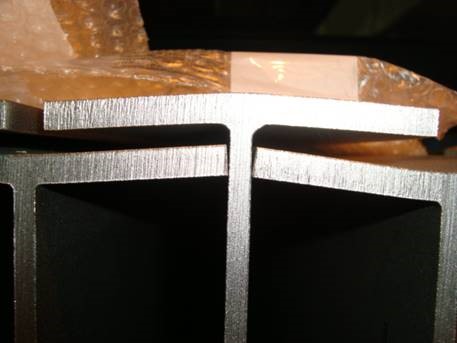

These standard profiles such as beams, channels, angles, and tees eliminate this issue because they do not have an interior wall for the water to gather and deteriorate. However, the water or disinfectant can still build up and form collections on the straight flanges of the beams. Any pooling of water for an extended time can significantly increase the chance of decomposition. To eliminate this concern, we have developed a way to produce structural shapes with a 1 to 2 degree of downward slope on the flange. This allows for effective drainage of any fluids providing a sanitary structure. The picture above shows a laser welded 316/L stainless steel I-Beam with a 2 degree sloped flange that promotes water run-off.

Innovative Solutions

These sloped flange beams are just one example of how we use our production technologies to meet your design needs. No other technology allows for the customization of stainless or carbon steel profiles like laser welding. Whether it be an industrial application or an architectural design, our team is ready to help find the perfect solution for your project. Contact us today for more information or to request a quote.