How to choose an impact wrench? How to choose tyre service and car repair tools

How to choose the best impact wrench? Read on and learn more about picking the right impact wrench.

An impact wrench is one of the most useful tools at a car workshop or tyre service. Carefully chosen, it provides comfortable work, not only with wheels, but also other elements in the car. See what to look for when choosing a impact wrench for further resale.

See what to look at while choosing an impact wrench for your clients’ workshop. Here are the 5 most important factors to keep in mind:

- maximum torque

- degrees of tightening / loosening

- wrench’s air consumption

- noise level

- type of casing

What is it all about? Read on below.

Max. torque of the wrench

Why bother about a torque of 1450 Nm, when you can get wrenches with 1900 Nm? Or 2200 Nm? Or even 5000 Nm? The higher the value is, the more convenient it will be to work with it.

So what exactly is the torque thing about? This is the power that the wrench can generate in a short time – for example, when you first press the trigger. The higher the max. torque, the tougher screws it may handle.

But – never go too far. There is no need to get a wrench with max. torque of 2200 Nm, if your clients work with screws in “passenger cars” on a daily basis. Sometimes there is no point in more torque.

Remember that the maximum torque is the value only reached within first instances. At the highest speed. The torque is lower for the rest of the time. For example, for one of our devices, REDATS P-160 max. the torque is 1500 Nm and the working torque varies from 68 to 1054 Nm.

The fact is that pneumatic wrenches with a torque of 1500 Nm or 1900 Nm will easily deal with the majority of tasks in the workshop or tyre services dealing with passenger cars.

Degree tightening / loosening – how to understand?

Good pneumatic wrenches always have several degrees of torque adjustment. Let REDATS P-180 serve as an example. In this device there are 4 torque values that we can set:

- 4 degrees for tightening

- 1 degrees for unscrewing

Does it matter? The more degrees of torque control you have to choose, the more precise it becomes to work with the wrench. The tool becomes much more universal. We can tighten the pins in the passenger car and vans using one wrench. All it takes is switching between gears. Thanks to this, you will not screw the screw head or thread. Instead, you will dismount them safely.

Which housing is better? Metal? Composite?

Most of the cheap wrenches, which can be bought even at DIY stores, have casings made of metal. It may seem like an advantage. ell, since we use the key anyway in the workshop, where there is a risk of its damage or fall. Theoretically, therefore, metal will survive such impacts much better. Unfortunately, metal surfaces are sensitive to scratches or dents anyway.

And these are not their only drawbacks. Pneumatic wrenches with a metal housing are simply heavier. This is important when working for a long time. Also, imagine that you must touch such a metal key on a frosty morning. Well – not a pleasant feeling, right?

- Meanwhile, a key with a composite housing is usually a little lighter than metal counterparts. Here are examples:

- REDATS P-180: 2.3 kg

- REDATS P-160 – 2.2 kg

- REDATS P-120 – 2.1 kg

It is known that these are not big differences, but after a long work with such an impact wrench in hand it matters. Such a tool is also much better in the hand than a heavy wrench, so the work is much nicer.

Besides, the wrenches made of composite are also much more pleasant to touch. There is no question of a “cold” hilt on a cold morning. The composite does not so much absorb the cold from the air.

Air consumption

What is the meaning of this parameter? Knowing this value, you will be able to choose the right compressor to work with the wrench. It is worth remembering that usually it is only a MEDIUM value. Wrench’s air consumption can either rise or fall during work

Do not treat this parameter as key while choosing a wrench. It only has to help in the possible selection of the compressor for the device.

The noise level of the pneumatic wrench

What about the noise level? It can not be concealed that working with a pneumatic wrench can produce a lot of unpleasant sounds. Remember that it makes a noise both in the mechanism and in the part that is being worked on. This could be extremely tiring, especially during the tyre changing season. Throughout the day, employees of tyre services have to work with hundreds of wheels. Generally, every wrench makes noise, so suggest some hearing protection – for example, headphones or ear plugs.

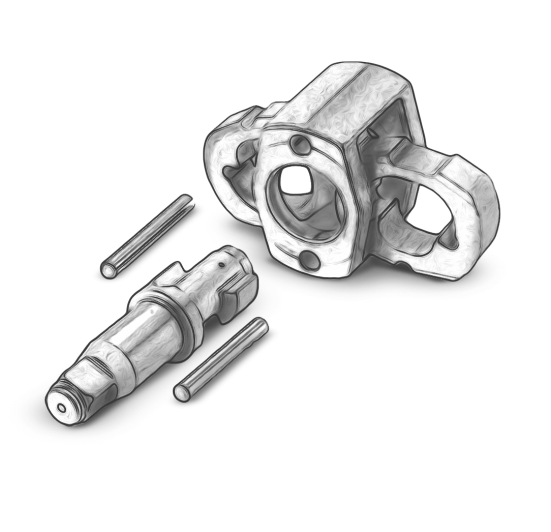

Twin Hammer – what is it?

This English-language means “double hammer”. In this solution, two hammers constantly rotate around the spindle. Thanks to this, the wrench is able to create a huge torque already in the first moments of work.

Will the Twin Hammer mechanism affect the wrench’s reliability? Good news is – it will not. Hammers that are used in this provide for trouble-free operation for years.

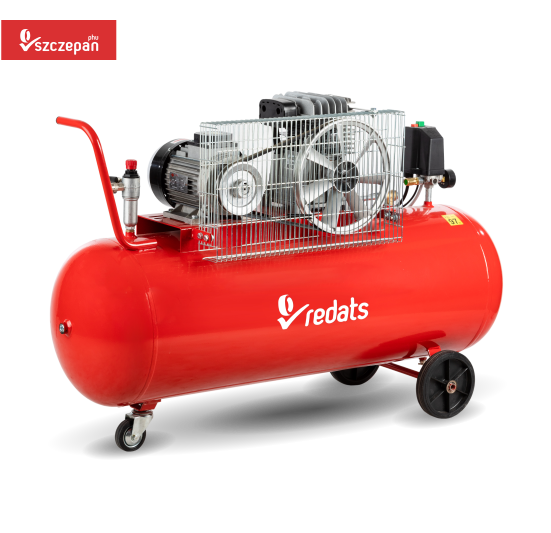

Which compressor for a pneumatic wrench?

Even the most powerful impact wrench will not be able to work without a compressor. Only how to choose the right compressor for the pneumatic wrench? Here are two rules

The impact wrench should have a capacity greater than or equal to the air wrench’s requirement. Only then will you be able to work without major interruptions.

So – if we have a wrench with air demand is on average 410 liters per minute, it is best to choose a compressor that will provide a capacity of at least 410l / min on the blow.

And if the compressor’s efficiency will be lower? Then, the whole system will work in intermittent mode. That is – not only the wrench will not reach its nominal power, but also will not be able to work without interruption.

And if the compressor capacity is clearly lower than what the wrench requires? Well, it’s going to work … but the compressor will stop giving the right amount of air from time to time, because it will have to create pressure in the tank.

What is the power of a compressor for an impact wrench?

A compressor is necessary for tyre service anyways. It can not be concealed, however, that the comfort of work will only be ensured by a 4-horsepower compressor. And often – even more.

The power of the compressor is important. But the efficiency on the blow is even more important.

The efficiency of the compressor

This parameter describes the device’s performance. What does it mean? This is the amount of air that is generated in minutes and which the compressor moves to the connected tools. Knowing what is the efficiency of the compressor on the blow, you will be able to determine if the 50L compressor is enough.

How to choose a compressor with efficiency, ensuring the right power of all devices in your workshop? Well – first of all, make sure what kind of air demand there are for particular tools that you use in your company. For ease of use, read this table.

| Compressor efficiency | Air consumption | Is it enough? |

| 150 L/min | 140 L/min | YES |

| 150 L/min | 150 L/min | NO |

| 640 L/min | 410 L/min | YES |

| 335 L/min | 410 L/min | NO |

As you can see from the table above, it is not worth choosing the devices whose efficiency is set “in contact” in relation to the demand of a given pneumatic tool for air. It is always good to leave a reserve. This will allow for trouble-free feeding of pneumatic tools, even during intensive work.

Impact wrench – how to choose?

Also, remember about maintaining the tool. While choosing a certain wrench, make sure the seller offers service. Even though you buy a completely new device and you should probably not be able to do anything … but – it’s better to stay on the safe side.

Choose an impact wrench from a company that will provide you with:

- service and possibly repairing the tool

- spare parts for the tool

Without the wrench, you will not be able to work on the site after all. In the event of a failure you suddenly become without a tool or you will have to buy more. And that’s the cost … And lost earnings, because you have nothing to work in the workshop / tyre repair service.

What pneumatic wrench for tyre services?

The most important factors here are such factors as

- max. torque

- price-quality ratio

How to understand? In tyre services, where you unscrew hundreds of screws per day, the pace of work is important. The higher the max. torque of the wrench, the more effective your work.

The following values could be assumed:

- additional device in tyre service:

- at least 1450 Nm,

- main device in passenger car tyre service: at least 1500 Nm,

- main device for tyre services for cars and vans: at least 1900 Nm,

- additional equipment (for really “difficult screws”): 2200 Nm,

- for tyre service dealing with trucks / agricultural machines: 5000 Nm

Check out REDATS’ impact wrenches here:

– https://redats.com/products/61/4/impact%20wrenches