Understanding the Differences: Sheet Metal Stamping and Metal Fabrication

Metal fabrication and sheet metal stamping are two widely used manufacturing processes for metal parts and components. These processes offer distinct advantages and are chosen based on specific requirements. In this article, we will explore the differences between metal fabrication and sheet metal stamping, and how geosynthetic material can play a role in enhancing these processes.

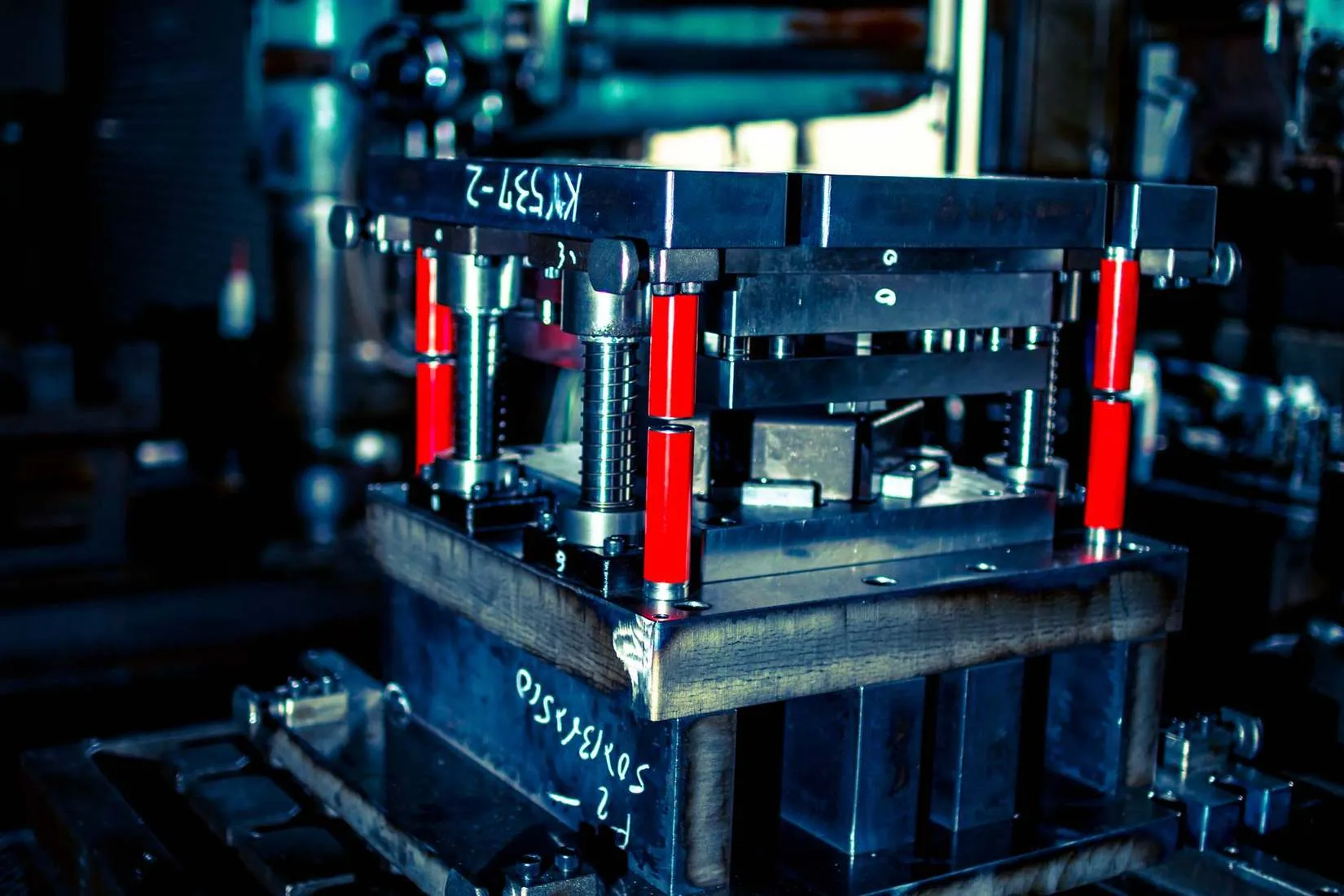

What is Sheet Metal Stamping?

Sheet metal stamping is a cost-effective fabrication process that utilizes dies, punches, and other tools to shape sheet metal into the desired component. It can be done in a single or multiphase process, with progressive die stamping being a common approach. In progressive die stamping, a strip of metal is pulled through different tooling stations, each performing specific punches, cuts, or bends. This method allows for complex designs, high repeatability, and secondary processing options.

The Advantages of Sheet Metal Stamping

Sheet metal stamping offers several advantages:

- Lower cost per piece for larger production runs: With efficient tooling and automation, sheet metal stamping becomes cost-effective for large quantities.

- Capable of complex designs: The versatility of stamping tools enables the creation of intricate and precise designs.

- Highly repeatable: The process ensures consistent results, making it suitable for high-volume production.

- Secondary processing available: Additional operations such as plating, painting, or assembly can be easily incorporated into the stamping process.

Integrating Geosynthetic Material in Sheet Metal Stamping

Geosynthetic materials, known for their durability and strength, can enhance sheet metal stamping processes in various ways. By incorporating geosynthetics into the tooling design or as part of the die material, manufacturers can achieve improved wear resistance, reduced friction, and enhanced product quality. Geosynthetics can also help minimize material adherence, leading to smoother sheet metal forming and reducing the need for lubrication.

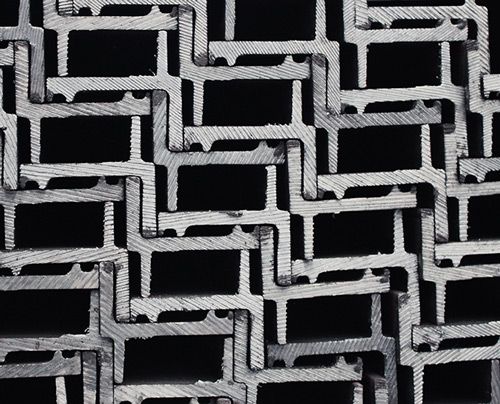

What is Metal Fabrication?

Metal fabrication encompasses a broader range of manufacturing processes, including cutting, bending, and punching, to shape metal components. It is often chosen for applications that require rapid prototyping, diverse customization options, and quick design adjustments. However, it can be more labor-intensive and time-consuming compared to sheet metal stamping.

Advantages of Metal Fabrication

Metal fabrication offers the following advantages:

- Rapid prototyping: The flexibility of fabrication techniques, such as laser cutting and shearing, allows for the quick production of prototypes.

- Versatile fabrication techniques: Various methods can be employed to achieve different shapes and designs, providing customization options.

- Diverse customization options: Metal fabrication allows for a wide range of design possibilities, catering to unique requirements.

- Quick and easy design adjustments: Design modifications can be implemented swiftly during the fabrication process.

Integrating Geosynthetic Material in Metal Fabrication

Geosynthetic material can also play a valuable role in metal fabrication processes. For instance, incorporating geosynthetics in laser cutting operations can improve cut quality, reduce heat-affected zones, and minimize material distortion. In addition, geosynthetic liners can enhance bending operations by reducing friction, preventing scratches, and ensuring accurate angles. By leveraging the properties of geosynthetics, manufacturers can optimize their metal fabrication processes.

Choosing the Right Process for Your Metal Products

When selecting between sheet metal stamping and metal fabrication, it’s crucial to consider factors such as production volume, complexity of design, and cost. Sheet metal stamping is ideal for large production runs with complex designs, while metal fabrication suits applications requiring rapid prototyping and customization.

By integrating geosynthetic materials into these processes, manufacturers can further enhance their efficiency, reduce wear and tear, and improve overall product quality. Whether you opt for sheet metal stamping or metal fabrication, geosynthetics can be a valuable addition to your manufacturing toolkit.

Quality Metal Stamping and Fabrication Services

If you are in need of reliable metal stamping and fabrication services, Engineering Specialties, Inc. (ESI) is a trusted provider. With decades of experience and state-of-the-art automated systems, ESI delivers high-quality manufacturing solutions. Our skilled team, including Six Sigma Black Belt Trained QA personnel, ensures precision and excellence across all our products and services. Contact ESI today to discuss your metal stamping and fabrication requirements.