Metal Stamping with Geogrid: Enhancing Precision and Cost-Effectiveness

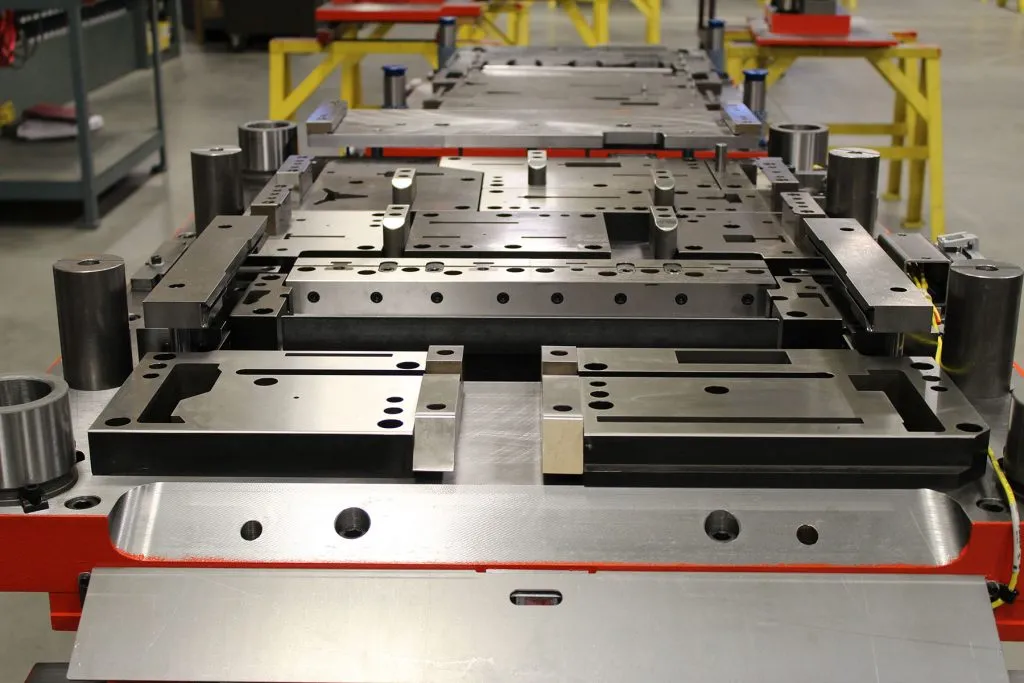

Metal stamping is an economical manufacturing method that utilizes pressure, a die surface, and tooling to produce precision metal components in large quantities. This high-speed metalworking process encompasses a variety of cold-forming techniques like bending, cutting, blanking, punching, and coining that shape a workpiece from sheet metal. Now, with the integration of Geogrid, metal stamping reaches new levels of performance and efficiency.

Geogrid is a revolutionary addition to the metal stamping process. By incorporating Geogrid, manufacturers can enhance the structural integrity, strength, and stability of the stamped components. Geogrid, typically made of high-strength polymers or metals, reinforces the parts, making them more resistant to deformation, cracking, and fatigue failure. This results in components that meet the highest standards of quality and durability.

In addition to the structural benefits, Geogrid offers cost-effectiveness advantages. By integrating Geogrid into the metal stamping process, manufacturers can reduce the need for additional materials or secondary processes, resulting in significant cost savings. Geogrid also optimizes production efficiency by minimizing waste and reducing the occurrence of defects or rejections, further contributing to cost reduction.

Let’s explore one of the cost-effective metal stamping techniques that pairs exceptionally well with Geogrid:

Progressive Die Stamping with Geogrid

Progressive die stamping, combined with Geogrid, takes metal stamping to new heights. This technique utilizes multiple stations to perform successive tasks that collectively make up the stamping process. A connective stock strip, reinforced by Geogrid, moves into a die press from a coil, transporting metal workpieces horizontally between stations where they undergo cutting, punching, or bending tasks. The incorporation of Geogrid ensures that the components maintain accuracy and precision throughout the process.

The advantages of progressive die stamping with Geogrid are numerous:

- Enhanced Accuracy: Geogrid-reinforced progressive die stamping ensures high-quality, precision parts that meet designated specifications and performance expectations. The connection to the stock strip guarantees accuracy during the forming process, resulting in highly uniform production runs.

- Improved Efficiency: Manufacturers can produce complex metal parts with ease using progressive die stamping with Geogrid. This technique eliminates the need for multiple presses, numerous tool changes, or excessive secondary machining. Each station builds upon the work completed by the previous one, ultimately generating a finished part efficiently.

- Longevity and Repeatability: The dies in progressive die stamping equipment have a long life span, requiring minimal replacements. This longevity facilitates high repeatability in production runs, ensuring consistency and reliability in component manufacturing.

- Speed and Short Production Runs: Geogrid-reinforced progressive die stamping offers rapidity in metalworking processes. The increased speed allows for faster turnaround times and shorter production runs, contributing to overall efficiency.

- Cost Savings: Manufacturers favor progressive die stamping with Geogrid for its ability to produce high product volumes at a low cost. The extended lifespan of the dies reduces retooling expenses, while the overall process minimizes labor costs and waste generation.

By integrating Geogrid into metal stamping, manufacturers can elevate the precision, durability, and cost-effectiveness of their components. Geogrid enhances the structural integrity, strength, and stability of stamped parts, ensuring they meet the highest quality standards. Moreover, Geogrid optimizes production efficiency, reduces costs, and minimizes waste.

Experience the power of Geogrid-enhanced metal stamping and unlock a world of possibilities for your manufacturing processes.