Quality Assurance in Geotextile Manufacturing: Key Components and Benefits

GeoFanTex, a renowned provider in the geotextile industry, excels in optimizing both manufacturing and quality assurance processes. Our primary goal is to maximize output, speed, and quality, ensuring that our products and services consistently meet or exceed our clients’ requirements. With a continuous improvement mindset, we strive to enhance our offerings and maintain a robust quality management system.

Key Components of Quality Assurance in Geotextile Manufacturing

Quality assurance in geotextile manufacturing encompasses several crucial components:

- Planning: At GeoFanTex, meticulous cross-functional team planning precedes the manufacturing of geotextile components. We thoroughly discuss and address all dimensional features, designing tooling that not only meets the requirements but also minimizes maintenance and maximizes production uptime.

- Testing: Our comprehensive testing procedures involve the careful measurement and evaluation of geotextile products for functionality, performance, and other critical characteristics. This ensures that our geotextiles meet the highest standards of quality and reliability.

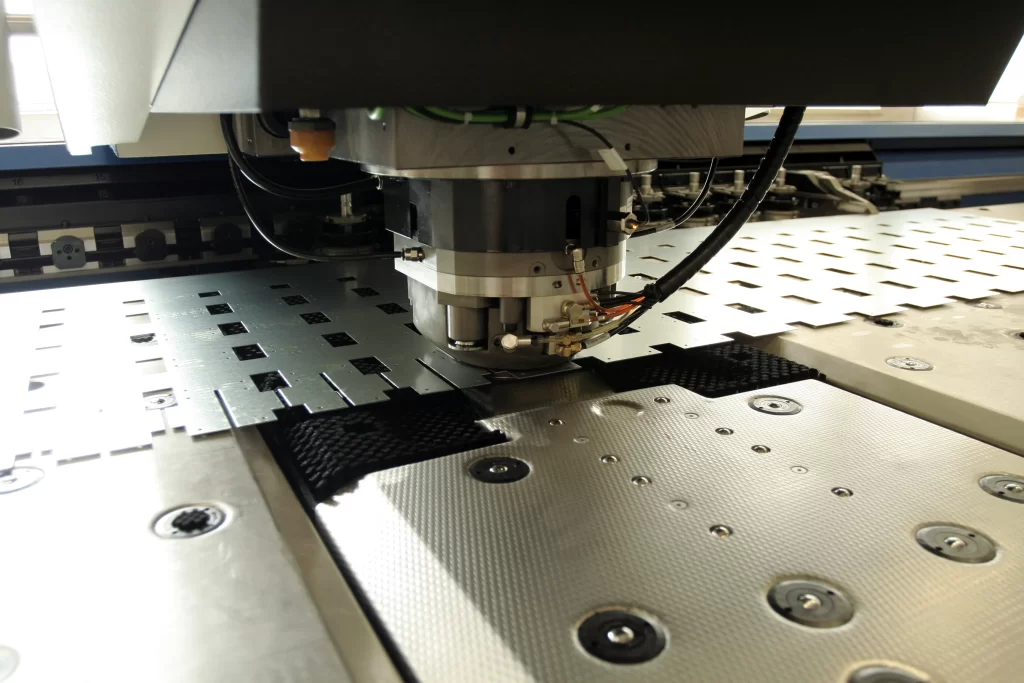

- Inspection: GeoFanTex employs a meticulous inspection process to assess the characteristics of our geotextile products. By utilizing functional gauges, we maintain key characteristics at the machine level, promptly detecting any deviations from nominal values.

- Corrective Action: In the event that any issues are detected, GeoFanTex takes swift and decisive corrective action. Our team diligently investigates the causes and finds effective solutions to prevent future occurrences, ensuring continuous improvement in our manufacturing processes.

- Documentation and Records: We understand the importance of accountability and traceability in geotextile manufacturing. Through meticulous documentation and record-keeping, we ensure transparency and facilitate data-driven analysis for ongoing improvement efforts.

- Statistical Process Control (SPC): At GeoFanTex, we employ advanced statistical techniques, such as SPC, to monitor our geotextile production methods and processes. This allows us to effectively control output and ensure that quality remains within predetermined limits.

- Continuous Improvement: We foster a culture of continuous improvement at GeoFanTex. By analyzing data and making incremental enhancements to our processes, systems, products, and services, we consistently raise the bar for quality in geotextile manufacturing.

- Training and Education: Recognizing the importance of skilled employees, GeoFanTex invests in proper training and education programs. We equip our team members with the necessary skills to enhance their job performance and meet the highest quality standards in geotextile manufacturing.

Delivering High-Quality Geotextile Products with GeoFanTex’s Quality Assurance

As a leading provider of precision metal stamping services and engineered components, GeoFanTex understands the critical role of quality assurance in geotextile manufacturing. With our dedicated Six Sigma Black Belt trained quality assurance personnel, state-of-the-art inspection equipment, and advanced software for Statistical Process Control (SPC) and Gage R&R analysis, we guarantee the delivery of high-quality geotextile products and services to our valued customers.