The Benefits of Cold Drawn Steel Products

Cold drawn technology to produce bars and custom shapes is very beneficial. This article explains how you may benefit from cold drawn bars over traditional steel.

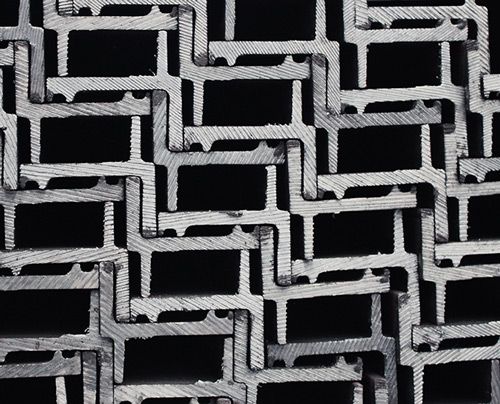

Cold Drawn Production

Cold Drawn Production

Cold drawn bars and shapes come in many forms. The procution method of cold drawing is a precision process: a series of one or more dies is forming a hot coil or billet at room temperatures. This creates the shape needed. The process can be used to extrude or shape a number of different bars in both regular carbon steel and stainless steel. The bars tend to be up to 20 feet in length or shorter. One can also use them for applications that are quite complex and have tight tolerance requirements.

Benefits of Cold Drawn Parts

There are many benefits to using cold drawn steel parts. Probably the biggest benefit is that cold formed parts have tighter tolerances and section properties which allow for less machining and improved straightness. This allows for better formability of these parts. Another benefit is the improved surface finish. One can easily tell a difference between a hot rolled bar and a cold rolled bar just from its appearance. Improved mechanical properties and higher yield as well as tensile strengths are also major benefits of cold formed steel. All of these benefits add up to the last major advantage which is cost effectiveness. Less machining, less scrap and better surfaces equal more time and more money saved.

Cold Drawn Applications

Most of the typical applications for cold formed parts for either carbon or stainless steel will overlap. These include pump parts as well as valve stems, linear guide rails or sprockets. Furthermore, they can be gears, keyways, splines and spindles. Turbine parts, curtain wall and facade constructions are also possible. They even include x-ray equipment, louvers, and couplings.

Industries Served

Next to automotive, industries served include power generation, food processing, aerospace, water treatment as well as pulp and paper, fluid engineering and chemical processing. Cold formed applications also include nautical, dental, medical, hand and power tools. Furthermore, you can find them in action for oil drilling, safes and vaults as well as for defense, appliances or textile. Last but not least, you can use them for elevators and escalators. In short, you can use cold drawn stainless steel and carbon steel sections in areas requiring precision tolerances and a superior finish.

Availability

Stainless Structurals, via our parent company Montanstahl, strives to produce cold drawn parts that exceed expectations. We only require three to five tons order minimum depending on the size and shape. We can produce cold formed parts in many alloys, especially in stainless steel. Please contact us today for your next cold drawn shape requirement.