Stainless Structurals in 2023: Reinvesting for Sustainable Growth

BlogStainless Product

2023 has been an exciting year for Stainless Structurals. This year we were focused on reinvesting in the company by adding new equipment, expanding our product offerings and starting green initiatives. We realize these steps are crucial for our long-term growth, sustainability, and competitiveness.

Innovative Equipment for Expanding Product Lines

In 2020, Stainless Structurals completed our expansion of our production facility from 110,000 SQ FT to our current footprint of almost 250,000 SQ FT. This expansion was done with the vision that we would need to add new equipment and capacity to our production lines. We were very strategic about these additions making sure they were innovative, allowing us to stay ahead of competitors and adapt to changing market conditions.

Our first equipment addition in 2023 was a new stainless steel polishing line. Over the years we have had many requests to provide a polished finish on our stainless steel structural items as well as flat bars for both architectural and industrial applications. With the new line, we can provide stainless steel polished finishes in a #4, #6, #8, Non-Directional, and RA finishes.

The second addition this year was a new low-impact laser welder. This 8KW welder was installed over the summer. The low-impact laser welder allows us to weld pre-polished and smaller geometries and increases our technical capabilities with the ability to laser weld lighter gauge material as thin as 1/8”. More complex geometric profiles are also possible on this low-impact welder and it gives us the ability profiles from 1/2”x 1/2” up to 36” x 20” parameters.

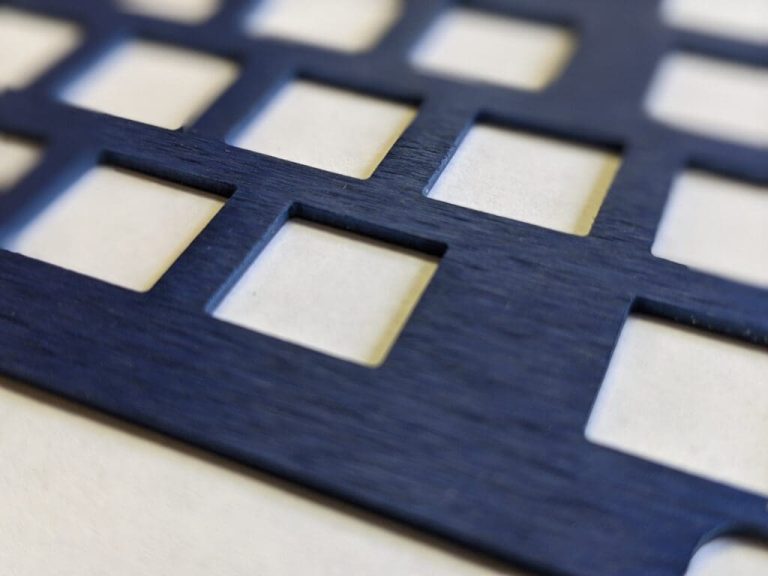

Just completed in November of this year was the installation of our new laser cutter. This LVD 20KW fiber laser is one of the largest laser beds in all of North America, measuring at 11’ x 78’. This modular table design allows for us to do laser cutting on one side, while loading and unloading on the other. It also gives the ability to cut up to 1-1/2” thick stainless steel plate and gives us the ability to produce longer profiles if required.

Sustainability and Green Initiatives

Reinvesting in sustainable practices not only contributes to environmental and social responsibility but can also appeal to conscious consumers. This past year, Stainless Structurals started several new facility projects with a focus on sustainability and renewability. We are committed to reducing our environmental impact by reducing waste and conserving energy and resources.

This year we became platinum certified by the Green Business Bureau. This was achieved by practices such as implementing remote work, sourcing raw material from sustainable suppliers, scrap recycling and much more. This last calendar year we recycled over 250 tons of stainless and carbon steel. We are also in the beginning phase of installing solar panels on our warehouse facility for power generation.

The Future is Now

Reinvesting in a business is essential for adapting to market dynamics, sustaining growth, and ensuring long-term success in a competitive business environment. It allows a company to stay relevant, innovative, and sustainable. The initiatives we have taken this year will pay dividends for our customers, employees and environment. For today and tomorrow. Contact our team today for more information on extruded steel profiles, stainless structurals, polishing, fabrication, and more.