Passivation and Pickling of Stainless Steel

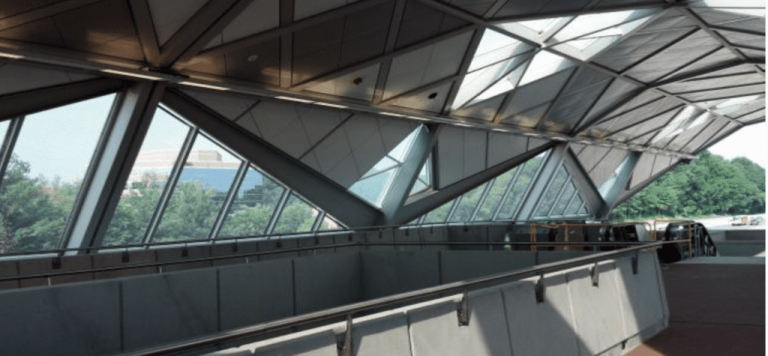

Architects and engineers look at many different factors when selecting which building materials to use for their projects and designs. The one key characteristic for choosing stainless steel is its corrosion resistance. Finishing treatments like passivation and pickling are what help stainless steels keep their corrosion resistance for so long.

Pickling is a very similar process to passivation. Pickling is the removal of any high temperature scale and the low chromium layer of the steel surface by a chemical treatment such as nitric or hydrofluoric acids. Because pickling involves a removal of metal layers, it can sometimes cause a change in appearance.

Passivation and Pickling

Passivation is a chemical treatment to the surface of stainless steel that removes contaminants such as free iron and helps form an oxide layer that protects the steel from corrosion. This can be done with either a nitric or a citric acid solution and it generally will not result in a marked change in appearance of the stainless steel surface.

Both passivation and pickling processes are performed with dangerous acids and standard safety procedures should be followed. These acids are also extremely corrosive to carbon steel contamination and should be thoroughly rinsed or washed after the process. For reference, ASTM A380 is the Standard Practice for Cleaning, Descaling and Passivation of Stainless Steel Parts, Equipment and Systems.

The Finishing Process at Stainless Structurals

With all of our laser-fused profiles, Stainless Structurals uses a two-step finishing process to maintain the corrosion resistance. This same process is used for the many different stainless steel alloys that we produce profiles in.

The first finishing step after laser welding is a mechanical process to remove contaminants. This is where the profiles go through a machine blaster that uses stainless pellets to remove any impurities. The second step is the chemical process where the profiles go through a citric acid treatment and wash to remove any of the remaining contaminants and restore the long lasting corrosion resistance.

Historically, nitric acid was used in passivation but now many are using citric acid. Citric acid is a much safer option and has many advantages. One advantage is that citric acid is environmentally friendly. Another is that it does not introduce hazardous waste into the final bath. Citric acid also only removes the iron and not the other elements thus limiting the depth of the final chrome oxide layer.

After completion of the blasting and pickling to the surface, the profiles now have a nice matte finish with a very clean appearance. Many architects like the look of this blasted and pickled finish and have specified it into projects. This process is standard with all of our profiles. There also other finishing options to finished profiles available throughout the industry such as polishing. You can read more about those here.

Stainless Structurals can Meet Your Project Needs

Our team is ready to assist you with your next stainless steel or other sharp cornered profile needs. We are an industry leader in profile solutions for building construction, industrial and architectural applications. Contact us today to learn more about how we can help you meet your project needs.