Learn How to Netzsch Pumps Parts Like an Expert

Netzsch pumps are renowned for their reliability and efficiency in various industrial applications. Understanding the parts that make up these pumps is crucial for maintenance and troubleshooting. This article will guide you through the essential components of Netzsch pumps and how to master them like an expert.

Understanding Netzsch Pumps Parts

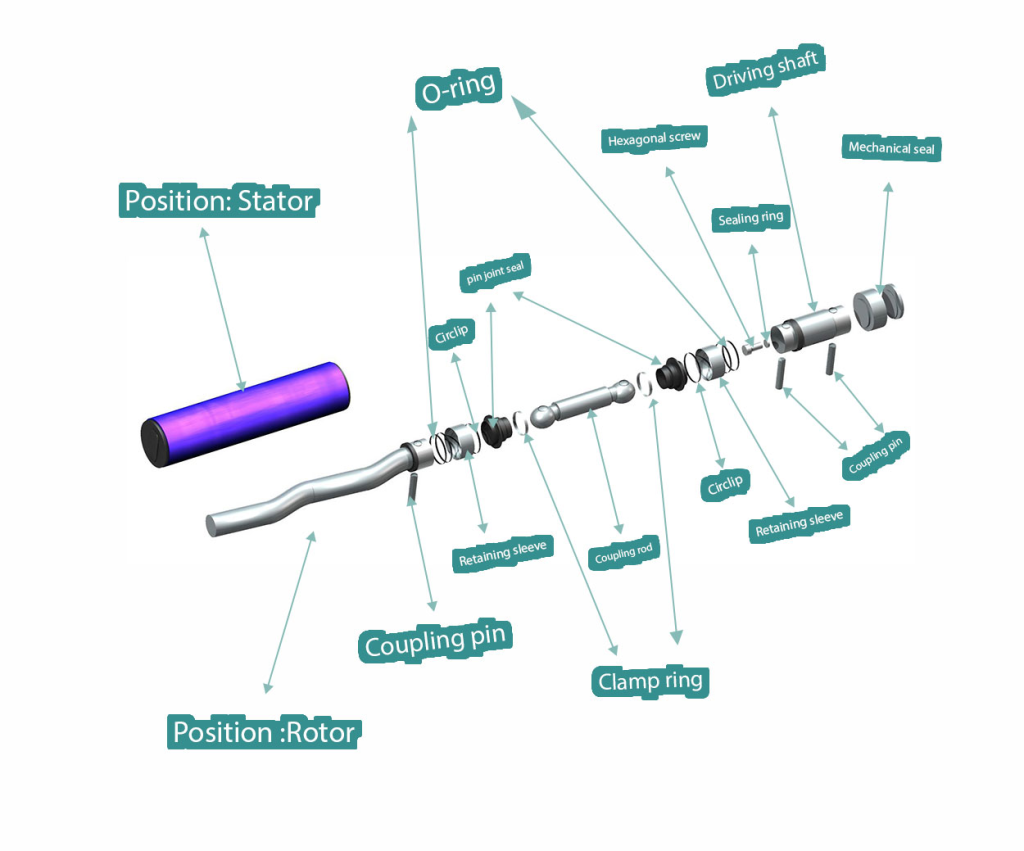

Netzsch pumps are designed with several critical parts, each serving a unique function. Familiarizing yourself with these components will enhance your ability to maintain and repair the pumps effectively. Here are the main parts you should know:

- Pump Head: The pump head houses the rotor and stator. It is responsible for creating the pressure required to move fluids.

- Rotor and Stator: These two elements work together to create a pumping action. The rotor rotates within the stator, drawing in fluid and pushing it out.

- Seal: Seals prevent leaks and maintain pressure within the pump. They are essential for ensuring the pump operates efficiently.

- Drive Mechanism: This component powers the pump. Understanding the different types of drives—mechanical, hydraulic, or electric—can help you choose the right one for your application.

- Suction and Discharge Ports: These are the entry and exit points for fluids. Proper configuration of these ports is vital for optimal performance.

Mastering Maintenance Techniques

To ensure your Netzsch pumps operate smoothly, regular maintenance is essential. Here are some expert tips for maintaining your pumps:

- Regular Inspections: Conduct frequent inspections to identify wear and tear on parts like seals and bearings.

- Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and wear.

- Cleaning: Keep the pump and its components clean to prevent blockages and contamination.

- Monitoring Performance: Use gauges and sensors to monitor the pump’s performance, helping you catch issues before they escalate.

Troubleshooting Common Issues

Even with proper maintenance, issues can arise. Knowing how to troubleshoot common problems with Netzsch pumps parts can save time and resources:

- Low Flow Rate: This may indicate a blockage in the suction line or wear in the rotor and stator. Check for obstructions and inspect the pump components for damage.

- Unusual Noises: Grinding or rattling noises can suggest that bearings are failing or that there is improper alignment. Investigate these areas promptly.

- Leaking Seals: If you notice fluid leaks, it may be time to replace the seals. Regularly check seals for wear and replace them as needed.

Conclusion

Becoming an expert in Netzsch pumps parts requires a combination of knowledge, hands-on experience, and proactive maintenance. By understanding the components, mastering maintenance techniques, and troubleshooting effectively, you can ensure the longevity and efficiency of your Netzsch pumps. With these skills, you’ll be well on your way to maintaining your pumps like an expert.