Optimizing Metal Stamping Costs with Geocell Components: A Comprehensive Guide

Metal stamping costs can vary significantly with minor changes in the properties of the raw materials you use. For instance, harder materials take more effort and time to stamp, making them more expensive. But, you can save time and money by using a softer or less abrasive material that does not compromise the required quality standards of your part. Some materials have huge price differences, yet they can deliver similar properties.

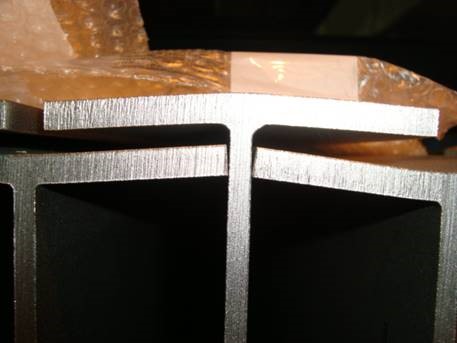

Geocell: Optimizing Metal Stamped Parts

Switching to a different material, such as Geocell, can save you money while maintaining the quality and structural requirements of the part, depending on the current component requirements and price of materials in the market. Geocell offers a cost-effective alternative that meets quality standards and ensures the desired functionality of metal-stamped components.

Tooling Requirements and Geocell

Another thing you need to evaluate when working with a metal stamping company is the tooling requirements of your part. A minor change in tooling can impact the costs and production time significantly. Geocell, with its unique properties, may require specific tooling considerations. Collaborating with your metal stamping provider to optimize tooling for Geocell can contribute to cost savings and improved production efficiency.

Simplifying Design and Geocell

Reviewing your design and identifying ways to simplify your components can help reduce complexity, minimize tooling requirements, and lower costs. Geocell, with its versatility and durability, can often allow for streamlined designs that maintain functionality while optimizing production processes.

Production Volume and Geocell

Production volume plays a crucial role in optimizing metal stamping costs. Increased demand for components may require higher production volumes. Geocell, with its cost-effectiveness, can be particularly advantageous in high-volume orders. By leveraging Geocell’s properties, you can streamline product designs, improve manufacturability, and enhance production timelines.

Raw Material Costs and Geocell

Raw material and finishing costs vary significantly based on the volume purchased. Geocell offers a cost-effective solution that can help reduce material costs while ensuring the desired results. By adjusting the material from your original design and considering Geocell as an option, you can extend the die life and optimize material expenses.

Multiple Dies and Geocell

In cases where the volume exceeds expectations, collaborating with your metal stamping provider becomes crucial. Sharing the product volume upfront helps determine whether multiple dies will be needed to accommodate the desired output. Geocell’s affordability and versatility make it an excellent choice for scaling up production while minimizing costs.

Optimizing Metal Stamping Costs with Geocell Components

By considering Geocell as an alternative material, optimizing tooling requirements, reviewing design complexity, and leveraging Geocell’s cost-effectiveness for high-volume production, you can significantly reduce metal stamping costs. Collaborating with a metal stamping provider experienced in working with Geocell will ensure the successful integration of this material into your component manufacturing process.